Challenges in present-day animal nutrition

manufacturing and labor

Avoiding cross-contamination

It is becoming more and more important to avoid cross-contamination in nutrition-producing factories. Whether the goal is to produce animal feed, pre-mixes, pet food or food for human consumption, the standard is getting higher all the time. At the same time, there are fewer operators who can maintain a human touch to keep quality standards high. And finally, a more demanding sales market also requires flexibility at the plant level. The risk of outgrowing a new factory within a few years is an enormous financial burden that should be avoided.

Automatic Container Transport (ACT)

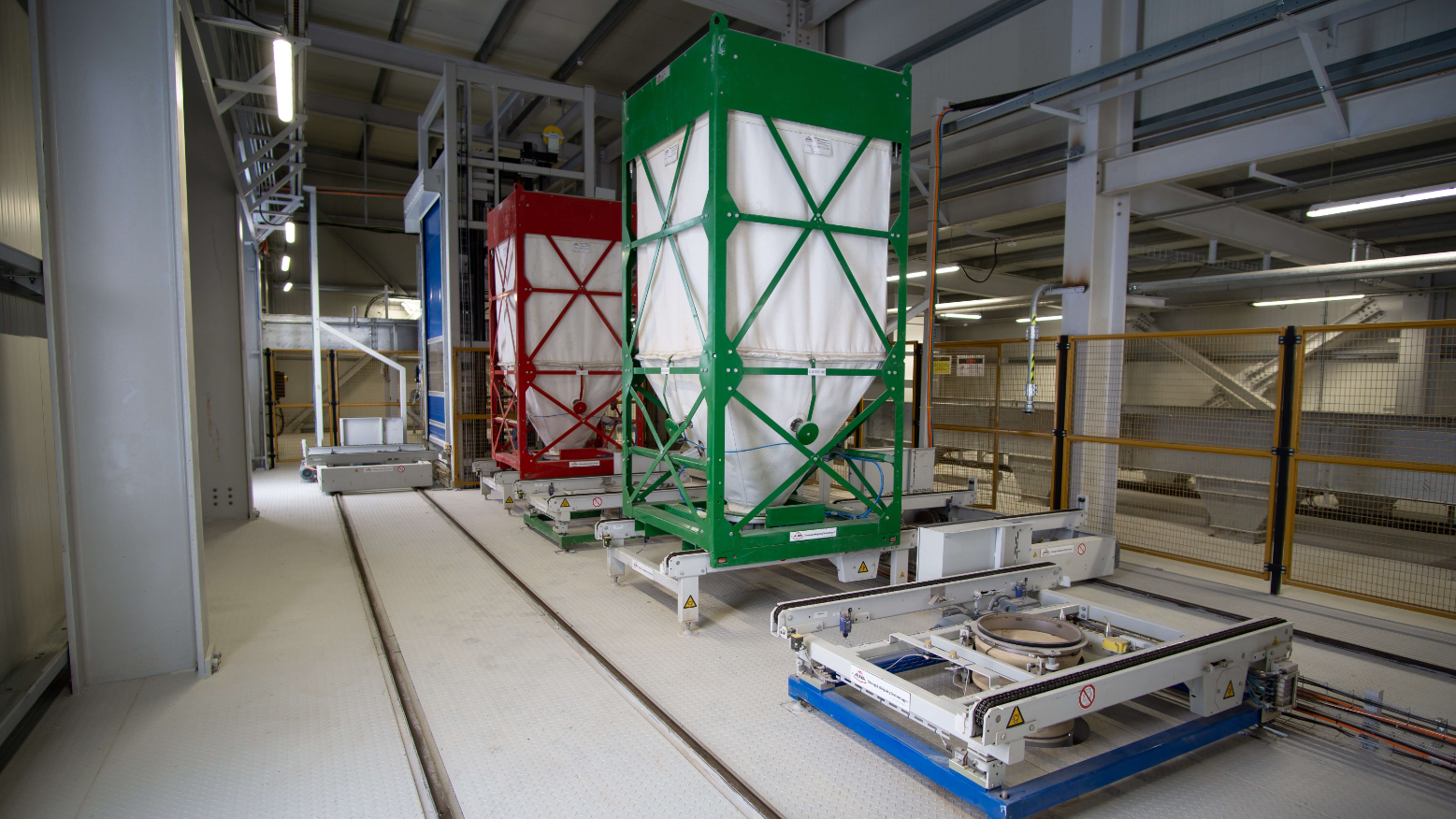

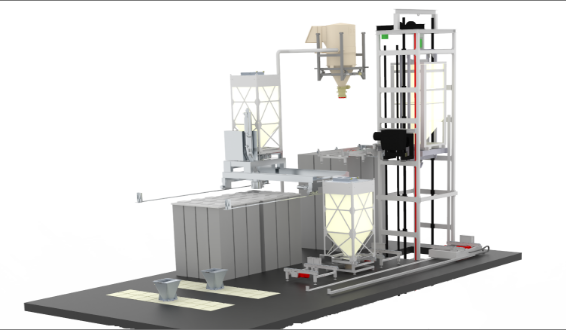

KSE Process Technology, based in the Netherlands, has therefore developed a transport system that allows factories to easily separate raw materials (e.g., different contamination groups) and batches of intermediate as well as finished goods, while running at maximum efficiency. Instead of using pneumatic transports and/or conveyer chains, the Automatic Container Transport (ACT) system uses dedicated containers of up to 5,000 kg each, which are then transported completely over a series of rails, elevators and mobile conveyers. The same containers can be used to store a larger and more flexible quantity of raw materials than in silos.

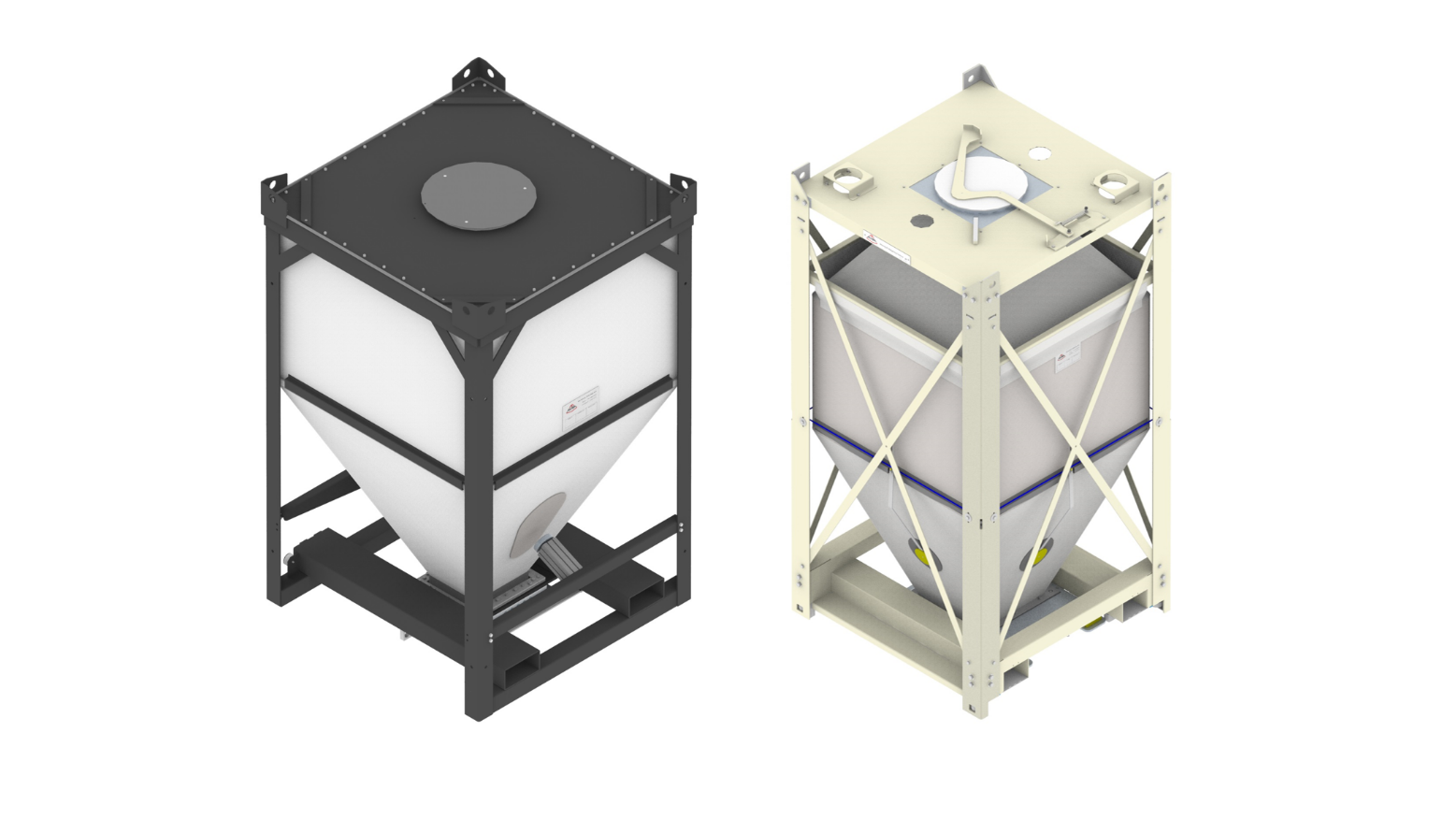

The containers consist of a steel frame with a specially developed fabric bag that is suspended within the frame. The fabric is reinforced and coated to make it durable and to keep condensation away from the product it holds. The containers are fitted with a unique agitating system that helps to prevent raw materials from being left inside when discharging. And finally, the containers can be fitted with RFID tags so that maximum traceability can be achieved.

In one of KSE’s most recent projects, we designed and implemented a complete pet food factory in the UK where the annual output is 140,000 mt/yr. The maximum height of this factory is 30 metres and their goal was to achieve zero contamination. To top it all off, only three operators are required to run this factory at maximum capacity

ALFRA ACT

A summary of the features of the ALFRA Automatic Container Transport equipment:

- Contamination-free storage and transport within the factory

- Fully modular set-up

- Different contamination groups can be transported on the same system

- Low maintenance and long operational life

Find out more about ALFRA machines to guarantee performance improvement for every step in your production process.