Adding weighing systems in limited building height situations

The benefit of a system with exchangeable containers

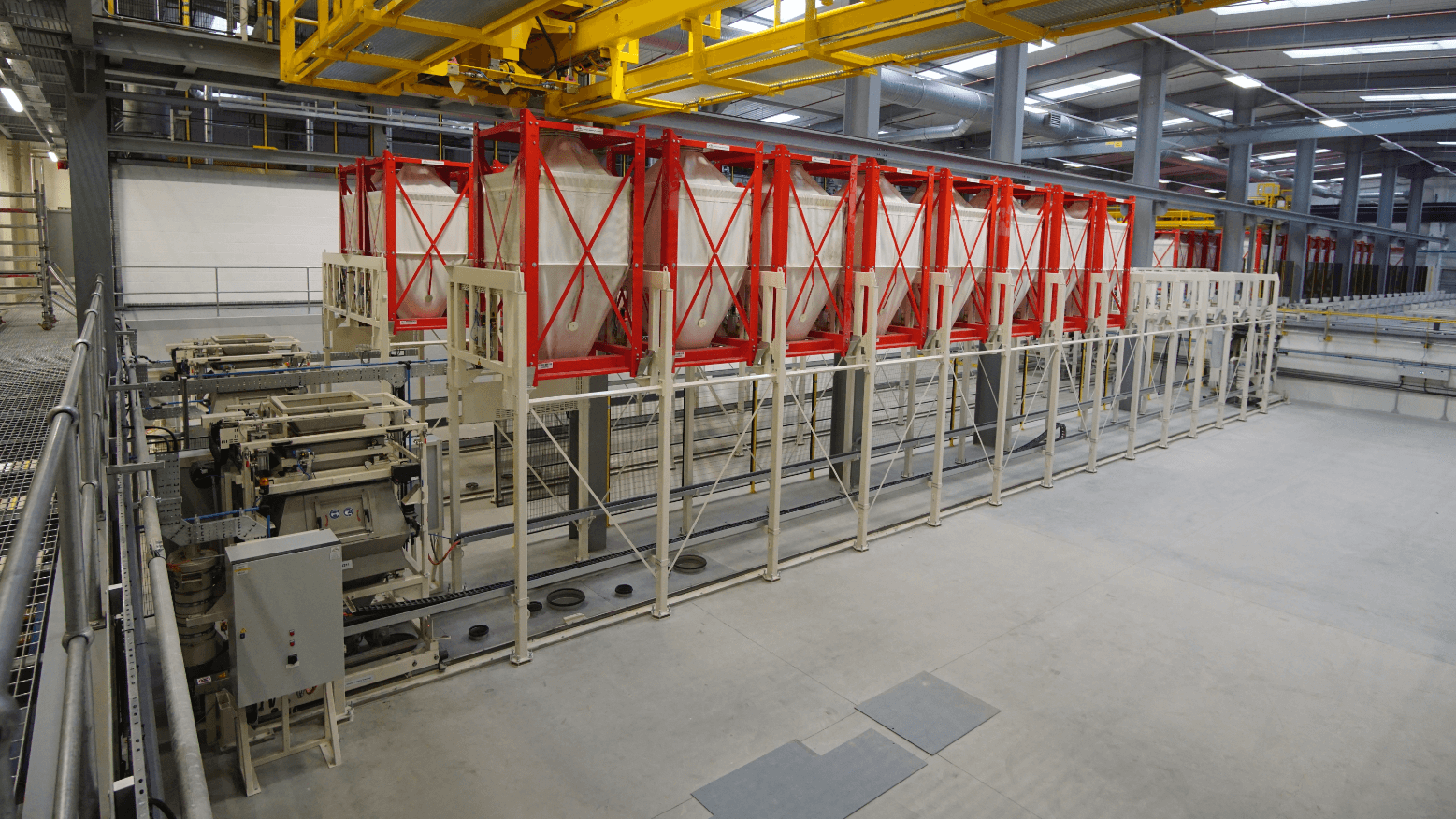

During feed and premix production, special additions and low volume ingredients often need to be exchanged for each new recipe. The challenge is to do this efficiently without needing a separate silo or manual additions for each ingredient. That is where our Container based dosing systems come in.

The key to success is a system of exchangeable containers (can hold 500-2000KG each) with dosing slides, realizing efficient and contamination-free dosing from small to large quantities. The containers can be used to store ingredients and can be exchanged easily to active positions on the weighing frame, to switch quickly between production recipes. These systems have enough active positions to dose and weigh up to 24 ingredients automatically.

The combination of high throughput and outstanding accuracy is captured in the unique dosing slide the GCCD features. This ensures that dosing and weighing no longer is a factory bottleneck. Notably, it prevents using labor-intensive and error-prone hand dosing – or an additional machine for dosing lesser amounts – by being able to handle from 100 grams up to a 1.000 kg in a single machine.

The smaller brother, designed for dosing the smallest micro ingredients is called FCCD. Uniquely, it eliminates labor-intensive and error-prone hand dosing – and the alternative of a separate machine for small amounts – by handling from 50 grams right up to 150 kg in a single machine.

A clean workplace is key

A clean workplace is a certainty with the extra features, like a built-in dust extractor which reduces cross contamination to the minimum or even zero. A large inspection hatch ensure cleaning, inspection and maintenance are all simple. The proven and optimized design ensures the running costs are low.

Get in touch