Knowledge farm

A growing source of information

Roger Bracewell, owner of GA Pet Food Partners in England, wishes to be able to guarantee that the produced petfood contains the exact prescribed recipe. To achieve that contamination-free production is imperative. Since the company works with almost 400 ingredients and over 800 different formulas, far-reaching changes were required, as well as joining forces by different professionals.

Premix producer Twilmij’s new plant has to double the current production of 50,000 tonnes per year. The first phase of the modern, man-hour saving 1,500m² production facility is ready. The integration of the fully automatic container transport system, which also prevents contamination, is a novelty in the premix branch.

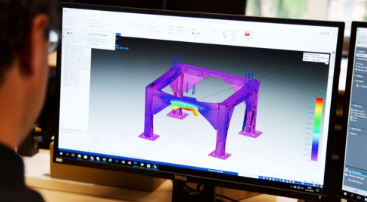

The design of a premix, compound feed or petfood production facility has one main goal: how to get all the raw materials into the end product(s). Of course in an accurate, time- and cost-efficient and flexible fashion with the desired capacity and footprint, while respecting any contamination groups. And last but not least, within budget.

Contamination can appear anywhere in the animal feed and premix production process at every premix plant. From intake to outloading, there are many possibilities for components to mix. Although contamination is receiving more attention at animal feed producers, it can be even more important for premix producers. Where should you look to avoid contamination? I’ve put together a simple overview to help you avoid it every step of the way.

One question that everyone faces in the livestock industry is what is an optimal production run? Are long production runs a more effective way of production and what are the right products and the right time to produce them? These are a few of the questions encountered recently in our webinar on “Big Data”. There was a considerable demand for delving into this subject, which is the reason why we are putting that to the test in this blog, especially since we know from experience that up to 25% additional output can be generated from the factory simply through good planning! Talking about a good ROI.

Everything needs to be produced greener and faster these days , while quality stays guaranteed. In other words, production needs to be more effective. But how do you determine if you produced more efficient this week compared with last week? To get the most production out of your machines, your factory needs to be configured in such a way that there are as few as possible machines. This sounds very logical. But how do you achieve that? It all starts with obtaining the right data.

The total compound feed production in the Netherlands is shrinking, but I don’t think that there is a drop in production. Of course this is because many small plants in the compound feed industry are closing. While the larger plants must produce more in the same factory. Often, there will be modifications to the plant to increase the capacity. More weighers, larger mixer or an additional press line are common extensions that are made to the current plant.